Subscribe to Our Mailing List

Get the latest news and updates with our Proximity Malt newsletters.

When examining sustainability, finding ways to enhance our practices and processes is crucial. We have often heard that you can’t improve what you don’t measure, but how do you measure sustainability in malt?

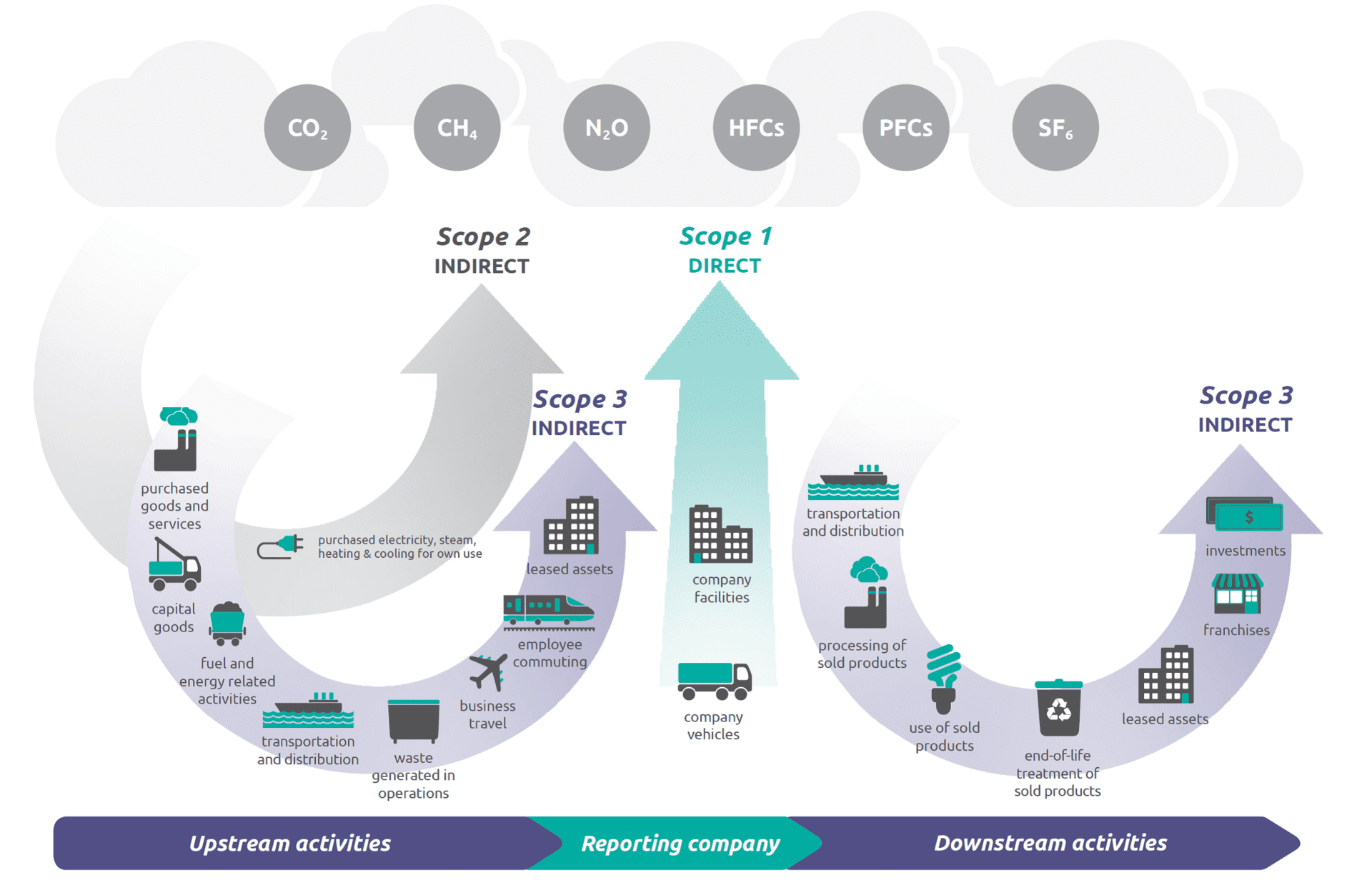

One approach to assessing sustainability involves measuring direct greenhouse gas (GHG) emissions resulting from all activities undertaken by an organization. Emissions are categorized as either direct or Scope 1 emissions (emissions originating from sources controlled by an organization) or indirect or Scope 2 emissions (emissions associated with the electricity, steam, heat, and cooling purchased to operate the organization’s facilities). Additionally, some emissions arise indirectly from an organization’s upstream activities (sourcing raw materials) and downstream activities (bringing products to market) and must be accounted for. These are classified as Scope 3 emissions. In the consumer packaged goods sector, agriculture has contributed significantly to these emissions.

Source: US Environmental Protection Agency Scope 3 Inventory Guidance

The Climate Smart Commodities Program

The United States Department of Agriculture believes that the agricultural sector holds incredible potential to provide lasting solutions to the climate crisis. It recently announced funding of up to U$3.1 billion for 140 selected projects. These projects explore ways in which regenerative agricultural practices can benefit the environment by reducing GHG emissions. The projects will assist farmers in measuring, reporting and verifying these practices. Finally, projects will develop markets for these products. Find more details here.

Proximity Malt is the only maltster chosen as a grant recipient. We committed to collaborate with our third-party sustainability verification provider to monitor field production practices for farmers enrolled in our program for tracking Climate Smart Commodities (CSC). We will provide educational opportunities for farmers using conventional production practices to transition toward growing regeneratively produced barley. Additionally, we will strive to create a marketplace to recognize and compensate those growers for reducing GHGe, improving soil health and diversity, and improving water management and stewardship. This page on our website will give more details.

Many customers prioritize environmental sustainability by concentrating on reducing Scope 1 emissions. Brewery operations will directly impact these emissions. According to a published Life Cycle Assessment resource provided by New Belgium Brewing, a sustainability leader in the US brewing industry, barley origination and malt sourcing constitute two primary categories of Scope 3 emissions that when combined, significantly contribute to a brewery’s overall emissions.

Breweries and distilleries purchase malts made from grains – primarily barley and wheat. Consequently, malt suppliers must explore ways to impact brewers & distillers’ Scope 3 emissions. resulting from both malt production, and barley origination.

Proximity Malt’s Climate Smart Program seeks efficiencies in the malthouse and expands our collaboration with our growers to identify, promote and measure regenerative agriculture practices. In summary, our Climate Smart Program impacts our customers’ Scope 3 emissions by:

We will launch this program in the coming months. We are excited to demonstrate to our customers how we will measure, report and verify these practices. Together, we can make a difference. Reach out to your sales rep to find out more.