Subscribe to Our Mailing List

Get the latest news and updates with our Proximity Malt newsletters.

From its inception, the Proximity Malt team sought to provide customers a domestic option to a wide range of exceptional malt flavors. Our full portfolio of malts and roasted products is made possible by our innovative ‘Continuous Coil’ roaster. If you’re interested in understanding the roasting process, visit our Roasting Malts page for more information.

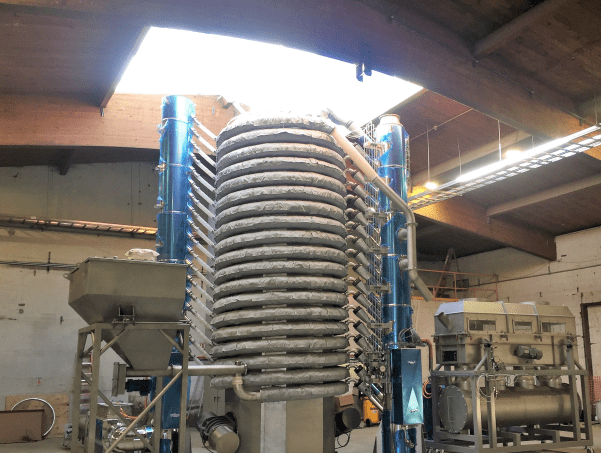

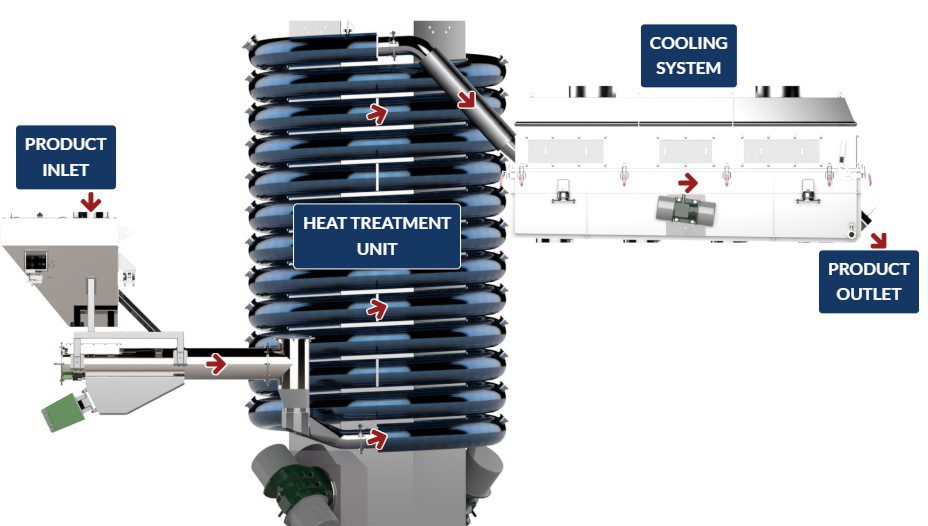

Both of our malting locations are equipped with Continuous Coil roasters. We also have a research and development pilot system in our Milwaukee headquarters. We use the pilot system to develop new flavors and products, and to improve our flavor and performance through ongoing attention to the roasting processes.

It’s hard to overstate the importance of the human factor when talking about great roasted malts. In true artisan fashion, creating great roasted grains is part science, part art. We bring these elements together through our team’s passion for translating grains’ potential into flavor, aroma and color. And we don’t lose sight of developing consistent, reliable products. Dialing in the potential of the Continuous Coil technology to produce delicious roasted grains has been key in Proximity’s art-meets-science journey.

Simply put, roasters provide much higher temperatures than kilns can produce When properly controlled, precise caramelization and crystallization of sugars occur through roasting as well.

Roasting results in a set of characteristics that brewers rely upon for flavor, aroma and color:

Similar to the kilning step in base malts, roasting of green malt stops grain growth and modification, but only after starches have begun a conversion to sugars. The intense heat provides caramelization and unique Maillard compounds which in turn create Crystal malts’ sweet, complex flavors.

Roasting exceptional grains relies on controlling four inter-related functions: time, temperature, airflow and grain motion. Our roaster innovates on the efficiency and control of each of these factors across the roasting process.

Importantly, the heat transfer is not made by hot air convection as in paddle roasters, but by direct contact with a hot surface which is electrically heated. This technology greatly reduces gas exhaust by a factor of ten, reduces fire risk and due to lower residency time of the grain, and reduces overall energy consumption as well.

In summary, green or raw grain (see below*) enters the spiral tube at a consistent flowrate. It’s heated up by direct contact with the hot, insulated tube and harmonic vibration causes product to progress up the coils. Temperature is maintained and the product is progressively roasted. The product is stabilized and cooled down, exiting the system at an ambient temperature, ready for packaging.

In the Continuous Coil roaster, our ability to precisely manage the process inputs provides important product improvements over traditional supply:

For more details on the benefits of our process, you can visit this page on our website.

Proximity Malt offers a full range of malts and roasted products, which you can visit here. Two types of roasting are commonly used in making our roasted malts:

If you or your brewing team would like more information on the science and art behind roasted malts, please let your sales rep know. We’d be happy to arrange for a virtual session to talk about how flavor, aroma and color are produced.